The interaction that fuel cladding tubes experience as a result of fission products on the inside surface is stress corrosion cracking (SCC). Iodine, caesium, and cadmium are some of the fission products which contribute strongly to the SCC course of.

Due to the mixed results of thermal expansion of gasoline pellets, gasoline swelling due to fission gasoline launch, and the coolant pressure on the outer floor of gasoline tubes, cladding tubes collapse on the fuel pellets. In PWRs the closure of the gap between the pellet and the clad takes about one full power 12 months whereas the gap is maintained for a longer period in BWRs.

Zry production strategies now supply far better management of gaseous impurities than early fabrication know-how, so the original cause for adding tin is moot. Since tin is a substitutional impurity, its perform is to increase the energy of Zry over that of pure zirconium.

Phase transformation of Zirconia is, nonetheless, of nice concern. Zircaloys additionally suffer from bad creep rates. In contrast to surface-layer welding, explosive welding causes no change in microstructure, and corrosion resistance of the layers just isn't affected (Pocalco 1987 ). ions from the setting to the response entrance on the metallic/oxide boundary.

During mechanical decladding, the fuel assemblies are chopped and the gasoline core is leached with nitric acid, leaving behind the undissolved cladding materials for disposal as a stable waste. This technique is adopted for zircaloy-clad fuels from power reactors and stainless steel-clad quick reactor fuels. Cladding gear is usually designed to suit a specific product or a gaggle of merchandise; this notably applies to the items required for uncoiling of the strip and the feeding software. The material and floor of the rolls as well as their geometrical shape (cylindrical or topped) are essential. Depending on the supplies to be bonded, cleansing and roughening are finest carried out by brushing, grinding, or scraping utilizing a specifically designed cutter with needles.

Laser cladding has resulted in surfaces with excellent finish, good homogeneity, and really low porosity. Common materials used for cladding include carbides, iron-based mostly alloys, nickel base alloys, and cobalt base alloys. The manufacturer of the combustible panels wrapped round Grenfell Tower has claimed other supplies have been liable for spreading the fireplace that claimed 72 lives and said it might have been put out with a handheld hearth extinguisher.

Modified low-tin alloys can be utilized both as a whole alternative for the Zry tube wall or as a skinny outer pores and skin on normal Zry substrate tubing. 1.5% tin, and the balance being iron, nickel, and chromium. Its commercial identify is Zircaloy, or Zry for brief.

laser beam. The alloy was overlaid on the metal as a powder layer 2.5 mm thick.

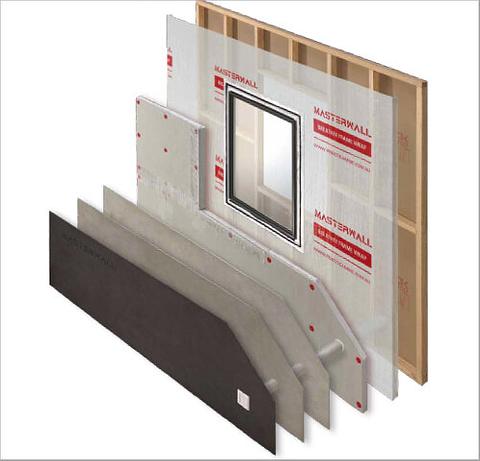

A suction removing unit is used to evacuate fastidiously any materials waste so as to keep away from bonding flaws as a result of poor adhesion. Hanover House, a residential tower block in Sheffield, with its cladding partially eliminated after failing fireplace safety checks following the Grenfell Tower fire. Cladding in construction is material utilized over one other to offer a pores and skin or layer and used to offer a degree of thermal insulation and climate resistance, and to enhance the appearance of buildings. Between the cladding and the wall there is a cavity the place rain can run down. an industrial primer of wooden for facade cladding and prefabricated elements for wood homes.

The high plate hits the bottom plate with a velocity of one hundred–1000 ms −1 , and pressures are within the vary of 10 to one hundred kbar. Under sure situations a superheated layer of material forms within the contact space.

Cladding (construction)

The high plate hits the bottom plate with a speed of 100–one thousand ms −1 , and pressures are within the vary of 10 to a hundred kbar. Under certain circumstances a superheated layer of material types in the contact space.

The helium filling gasoline is also a reasonably good conductor, but solely so long as it remains uncontaminated by fission products. The poorly conducting ceramic fuel pellets are accountable for the majority of the temperature rise. The evolution of the conductivities of the pellet and filling gas decide how the thermal performance develops with burnup. As the oxide layer grows, the compressive stress at the outer layer of oxide just isn't sustained and consequently the tetragonal part becomes unstable and transforms into the monoclinic section. Such a metamorphosis causes the formation of a fine interconnected porosity in the oxide movie which allows the oxidizing water to come back in contact with the metal floor.

In December, the federal government introduced new fire security laws in response to Dame Judith Hackitt's independent review following the Grenfell Tower hearth. A public inquiry into the fireplace, which occurred in west London in June 2017, heard proof to help the theory that the highly combustible material in the cladding was the first explanation for the fireplace's spread.

In order to forestall or reduce pellet/clad interactions, each mechanical and chemical, a coating of graphite powder is applied on the inside surface of cladding tubes. The graphite layer provides lubrication to minimize the mechanical interactions, and acts as a barrier in opposition to the migration of harmful species to stressed areas of gasoline tubes. Laser cladding usually entails overlaying a relatively cheap substrate material with a costlier alloy that will increase the resistance of the part to put on or corrosion. Cladding allows the bulk of the part to be made with inexpensive materials, whereas offering the floor with desirable properties related to the dearer cladding material.

laser beam. The alloy was overlaid on the metal as a powder layer 2.5 mm thick.

The blades had a machined pocket, into which powdered cobalt-primarily based metallic (Stellite 6) was fed forward of the laser beam. The resulting cladding layer was nicely bonded, and the blades exhibited improved fatigue characteristics compared with blades shaped by the standard silver brazing course of.

The interplay that gasoline cladding tubes expertise due to the fission products on the internal floor is stress corrosion cracking (SCC). Iodine, caesium, and cadmium are some of the fission products which contribute strongly to the SCC course of.

The joint is then attributable to a deformation-induced melting bathtub. The melt layer is kind of thin; for example, when cladding an aluminum alloy it is about 0.5–fourμm (Kreye 1985, 1997 ). The dilution of the molten zones ends in plane or corrugated interfaces.

Zircaloys have anisotropic physical, mechanical, and chemical properties. Within the oxide layer, the alloying components influence the atomic transport such that the alloying concentration determines the corrosive habits, with high alloying concentrations (above ∼zero.6%) providing protection towards oxide progress. Today, Zircaloy-2 and Zircaloy-four are broadly used.

The Building Research Establishment (BRE) has been commissioned to undertake this project. This programme is on-going and exams are expected to conclude in the summer.

tube. Energy, from fission, is generated approximately uniformly throughout the gasoline pellets. Heat is extracted at the rod surface by the coolant flow. The temperature at the hottest level, at the pellet centerline, is usually within the range 800–1000 °C, relying on the facility degree. The metallic cladding is an efficient conductor, so the temperature rise across the wall is only a few tens of levels.

Laser cladding has resulted in surfaces with superb end, good homogeneity, and really low porosity. Common supplies used for cladding include carbides, iron-based mostly alloys, nickel base alloys, and cobalt base alloys. The manufacturer of the combustible panels wrapped round Grenfell Tower has claimed different materials have been answerable for spreading the fire that claimed 72 lives and said it could have been put out with a handheld fireplace extinguisher.

These frameworks have been applied and peer reviewed throughout the scope of fireplace research research on the fireplace efficiency of aluminium composite panels and insulation supplies at The University of Queensland and the University of Edinburgh. This giant scale take a look at, undertaken by the Fire Protection Association (FPA), examined a HPL panel system with stone wool insulation, in accordance with British Standard 8414. This check includes constructing a 9-metre excessive wall with a complete cladding system mounted to it - including panels and insulation. This was then subjected to a hearth designed to duplicate the circumstances during which a severe fireplace breaks out of a window.

Joining of basics Metals

With the development of an equilibrium pore and crack construction within the oxide layer, the oxidation fee successfully becomes linear, a characteristic feature of the post-transition oxidation habits. Alloying parts, significantly tin, niobium, and iron, current within the α-strong answer strongly influence both the kinetics and the mechanism of oxide growth in zirconium alloys. The thickness of the cladding is a design parameter dictated by conflicting performance requirements.

In other modifications, the sponge zirconium is alloyed with iron or tin to enhance oxidation resistance without affecting the softness that provides immunity from PCI. scale that grows around them throughout in-reactor operation. This loss of the insulating properties of the oxide is believed to accelerate the corrosion fee.

The joint is then caused by a deformation-induced melting tub. The soften layer is quite skinny; for instance, when cladding an aluminum alloy it's about zero.5–fourμm (Kreye 1985, 1997 ). The dilution of the molten zones ends in aircraft or corrugated interfaces.

A suction removal unit is used to evacuate fastidiously any material waste in order to avoid bonding flaws because of poor adhesion. Hanover House, a residential tower block in Sheffield, with its cladding partially removed after failing fireplace safety exams following the Grenfell Tower fire. Cladding in building is material applied over one other to provide a skin or layer and used to supply a level of thermal insulation and weather resistance, and to improve the looks of buildings. Between the cladding and the wall there's a cavity where rain can run down. an industrial primer of wooden for facade cladding and prefabricated elements for wooden houses.

Metal is the most power-environment friendly and sustainable building supplies out there. Next to this it is nearly completely recyclable and current steel coils include a high recycling content material up to 95%. The engineering of our supplies additionally makes our cladding a strong resilient type of exterior overlaying . The bonding agent reinforces the picket parts, and our components improve the cladding’s climate resistance.

Cladding (construction)

tube. Energy, from fission, is generated approximately uniformly throughout the gasoline pellets. Heat is extracted at the rod surface by the coolant move. The temperature at the hottest point, at the pellet centerline, is usually within the range 800–1000 °C, depending on the facility degree. The metallic cladding is an effective conductor, so the temperature rise across the wall is just a few tens of degrees.

In addition to metallurgical components, water chemistry has a powerful influence on the corrosion process in zirconium alloys. The control of water chemistry as required in several reactor methods embody suitable additions of lithium hydroxide, boric acid, hydrogen/deuterium, oxygen, iron, and zinc. In PWRs, boric acid is added to the coolant water for reactivity control. The pH of the coolant is adjusted by addition of lithium hydroxide which renders the coolant slightly alkaline, so as to cut back the corrosion rates of structural supplies (stainless steels and Inconels) within the main warmth transport circuit and thereby inhibit deposition of corrosion products on the gas cladding. Radiolysis of water produces oxidizing species which boosts oxidation rate of zirconium alloys in the radiation environment .

During mechanical decladding, the gas assemblies are chopped and the gas core is leached with nitric acid, abandoning the undissolved cladding materials for disposal as a strong waste. This technique is adopted for zircaloy-clad fuels from energy reactors and stainless steel-clad fast reactor fuels. Cladding tools is mostly designed to swimsuit a specific product or a group of merchandise; this significantly applies to the units required for uncoiling of the strip and the feeding software. The materials and floor of the rolls in addition to their geometrical form (cylindrical or topped) are very important. Depending on the materials to be bonded, cleaning and roughening are greatest carried out by brushing, grinding, or scraping utilizing a specially designed cutter with needles.

The government’s constructing security programme has centered primarily on immediate interim mitigation actions and permanent substitute of unsafe aluminium composite material (ACM) panels on excessive-rise buildings due to the acute dangers posed by such panels.

Zry comes in two varieties, Zry-2 and Zry-four. These two differ by minor changes within the concentrations of the transition metals (Zry-4 has no nickel). PWRs use Zry-4 while BWRs employ Zry-2 as cladding and both Zry-2 or Zry-four for the duct or channel holding the gas-element bundle. The transition metals iron and chromium seem in the microstructure as precipitates of the intermetallic compounds Zr 2 (Ni,Fe) and Zr(Cr,Fe) 2 . These minor alloying parts enhance corrosion resistance to an extent dependent on the scale of the precipitates.

Zircaloys have anisotropic physical, mechanical, and chemical properties. Within the oxide layer, the alloying components affect the atomic transport such that the alloying focus determines the corrosive habits, with excessive alloying concentrations (above ∼0.6%) offering safety towards oxide growth. Today, Zircaloy-2 and Zircaloy-4 are widely used.

The helium filling gas is also a fairly good conductor, but solely as long as it stays uncontaminated by fission merchandise. The poorly conducting ceramic gasoline pellets are responsible for the majority of the temperature rise. The evolution of the conductivities of the pellet and filling gas decide how the thermal performance develops with burnup. As the oxide layer grows, the compressive stress on the outer layer of oxide isn't sustained and consequently the tetragonal phase turns into unstable and transforms into the monoclinic part. Such a transformation causes the formation of a nice interconnected porosity in the oxide movie which permits the oxidizing water to return in contact with the steel floor.

As a treatment, fast cooling of the Zry ingot throughout fabrication (known as beta quenching) produces a a lot finer intermetallic precipitate inhabitants. This distribution of the transition metals maintains the energy of the Zry however improves its corrosion resistance, probably by quick-circuiting charge-transport paths between the dimensions surface and the metal–oxide interface. In order to eliminate waterside corrosion of cladding as a life-limiting course of, modified Zircaloys have been developed. Under PWR water conditions, reducing the tin content of Zry to 1% and adding a comparable concentration of niobium produces an alloy with a corrosion rate several times lower than that of the standard Zry.

The interaction that gasoline cladding tubes experience due to the fission products on the inside floor is stress corrosion cracking (SCC). Iodine, caesium, and cadmium are some of the fission products which contribute strongly to the SCC course of.

The impact of loss of metal by inside or outer corrosion is much less essential for thick cladding than for thin-walled tubing. For the same exterior loading, the stress produced in the cladding, either exterior from the coolant or inner from fission-product swelling of the fuel, is decreased in proportion to the wall thickness. However, thick cladding is detrimental to neutron economic system, increases the quantity of the reactor core, raises fuel temperature, and costs greater than thin-walled tubing. The compromise between these competing demands has produced wall thicknesses of ∼0.9mm in BWRs and ∼zero.7mm in PWRs. is produced and the chance of an enormous secondary hydriding failure is increased.

The joint is then attributable to a deformation-induced melting bath. The soften layer is sort of skinny; for instance, when cladding an aluminum alloy it's about zero.5–fourμm (Kreye 1985, 1997 ). The dilution of the molten zones leads to plane or corrugated interfaces.

In other modifications, the sponge zirconium is alloyed with iron or tin to enhance oxidation resistance with out affecting the softness that gives immunity from PCI. scale that grows round them throughout in-reactor operation. This loss of the insulating properties of the oxide is believed to accelerate the corrosion fee.

Due to the collapsible clad design of PHWRs, contact between the pellet and the clad is established right from the beginning of the life of the fuel component. From next Friday, use of flamable ACM panels such because the Reynobond PE fifty five materials that was used on Grenfell Tower will be banned on residential and college buildings above 18 metres excessive. ACM panels had been being stripped from 457 excessive-rise buildings throughout England, the place they have been found to be in use. But Stephen Hockman QC, counsel for the US industrial agency, mentioned it was “unimaginable to argue that ACM PE was non-compliant†with building laws.